Wholesale Dealers of MW Professional Overhead Enclosed Track Driving Chain

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Wholesale Dealers of MW Professional Overhead Enclosed Track Driving Chain, We wholeheartedly welcome customers all over the world come to visit our factory and have a win-win cooperation with us!

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for China Chain Hoist for Line Array and Chain Conveyor Line, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality items to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We’ve got honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of “quality of survival, the credibility of development” for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

Product Description

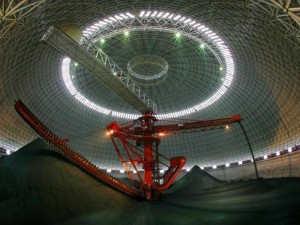

1-Baffle plate 2-Drive bearing house 3-Drive shaft 4-Sprocket 5-Chain unit 6-Supporting wheel 7-Sprocket 8-Frame 9 – Chute plate 10 – Track chain 11 – Reducer 12 – Shrink disc 13 – Coupler 14 – Motor 15 – Buffer spring 16 – Tension shaft 17 Tension bearing house 18 – VFD unit.

Main shaft device: it is composed of shaft, sprocket, backup roll, expansion sleeve, bearing seat and rolling bearing. The sprocket on the shaft drives the chain to run, so as to achieve the purpose of conveying materials.

Chain unit: mainly composed of track chain, chute plate and other parts. The chain is a traction component. Chains of different specifications are selected according to the traction force. The plate is used for loading materials. It is installed on the traction chain and driven by the traction chain to achieve the purpose of conveying materials.

Supporting wheel: there are two kinds of rollers, long roller and short roller, which are mainly composed of roller, support, shaft, rolling bearing (long roller is sliding bearing), etc. The first function is to support the normal operation of the chain, and the second is to support the groove plate to prevent plastic deformation caused by material impact.

Sprocket: To support the return chain to prevent excessive deflection, affecting the normal operation of the chain.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top