Professional Design Drag Conveyor / Scraper Conveyor / Forging Chain Conveyor

Usually customer-oriented, and it’s our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Professional Design Drag Conveyor / Scraper Conveyor / Forging Chain Conveyor, We’ll make bigger efforts that will help domestic and international prospective buyers, and generate the mutual profit and win-win partnership between us. we’re eagerly waiting for your sincerely cooperation.

Usually customer-oriented, and it’s our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for China Drag Conveyor and Redler, We have now been in operation for more than 10 years. We’ve been dedicated to quality goods and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a customized tour and advanced business guidance.

Instruction

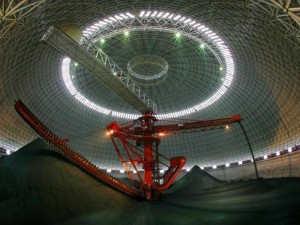

The scraper conveyor is mainly composed of a closed section casing (machine slot), a scraper device, a transmission device, a tensioning device and a safety protection device. The equipment has simple structure, small size, good sealing performance, convenient installation and maintenance; multi-point feeding and multi-point unloading, flexible process selection and layout; when conveying flying, toxic, high temperature, flammable and explosive materials , can improve working conditions and reduce environmental pollution. Models are: general type, hot material type, high temperature type, wear-resistant type, etc.

The overall structure of the scraper conveyor is reasonable. The scraper chain runs evenly and moves under the drive of the motor and reducer, with stable operation and low noise. Conveying equipment that continuously conveys bulk materials by moving scraper chains in a closed casing of rectangular section and tubular section.

Disadvantages

(1) The chute is easy to wear and the chain is seriously worn.

(2) Lower transmission speed 0.08–0.8m/s, small throughput.

(3) High energy consumption.

(4) It is not suitable to transport viscous, easy to agglomerate materials.

Our company has strict quality inspection means to ensure that the products delivered are high-quality products. Complete after-sales service system , to ensures that domestic engineers and technicians with rich experience will arrive at the designated site within 12 hours. Foreign projects can be solved through video conference communication.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top