The conveyor belt is a very important component of the belt conveyor system, which is used to carry materials and transport them to designated places. Its width and length depend on the initial design and layout of the belt conveyor.

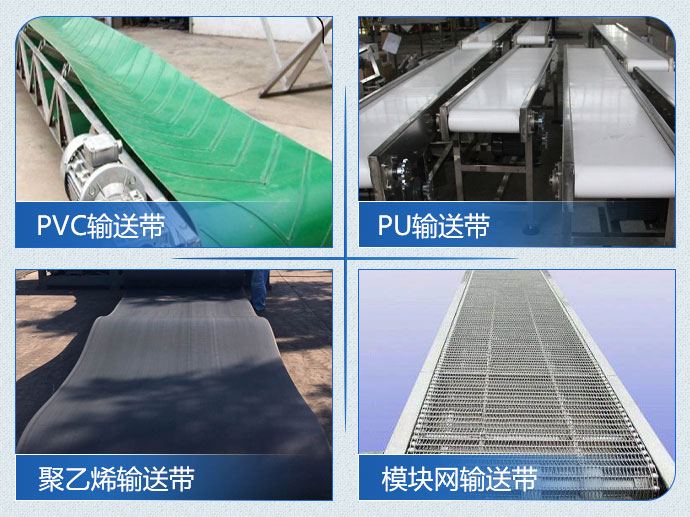

01. Classification of conveyor belt

Common conveyor belt materials can be divided into two categories: one is steel wire rope core, which has strong bearing capacity and good physical and mechanical properties, so it can meet the high-speed transportation demand under the premise of large transportation capacity; The second type is nylon, cotton, rubber and other materials, which are slightly inferior to the transportation volume and speed of steel wire rope core.

02. How to select the appropriate conveyor belt?

The selection of conveyor belt of belt conveyor is based on the factors such as conveyor length, conveying capacity, belt tension, conveyed material characteristics, material receiving conditions and working environment.

The selection of conveyor belt shall meet the following requirements:

Polyester fabric core conveyor belt should be selected for short distance belt conveyor. For belt conveyors with large conveying capacity, long haul distance, large lifting height and large tension, steel cord conveyor belt should be selected.

The conveyed materials contain blocky materials with large size, and when the direct drop of the receiving point is large, the impact resistant and tear resistant conveyor should be selected.

The maximum number of layers of layered fabric core conveyor belt should not exceed 6 layers: when the conveying material has special requirements on the thickness of the conveyor belt, it can be appropriately increased.

The underground belt conveyor must be flame retardant.

Connector of conveyor belt

The joint type of conveyor belt shall be selected according to the type of conveyor belt and the characteristics of belt conveyor:

The steel cord conveyor belt shall adopt vulcanized joint;

Vulcanized joint should be used for multi-layer fabric core conveyor belt;

Adhesive joint or mechanical joint should be used for fabric whole core conveyor belt.

The type of vulcanization joint of the conveyor belt: the layered fabric core conveyor belt should adopt the stepped joint; The steel cord conveyor belt can adopt one or multiple vulcanized joints according to the tensile strength grade.

Safety factor of conveyor belt

The safety factor of conveyor belt should be selected according to different conditions: that is, for general belt conveyor, the safety factor of wire rope core conveyor belt can be 7-9; When the conveyor to take controllable soft start, braking measures, desirable 5-7.

03. How to select bandwidth and speed?

1. Bandwidth

Generally speaking, for a given belt speed, the conveying capacity of the belt conveyor increases with the increase of the belt width. The conveyor belt must be wide enough so that the large blocks of the transported block and powder mixture will not be placed close to the edge of the conveyor belt, and the internal size of the feeding chute and the distance between the guide chute must be sufficient to allow the mixture of various particle sizes to pass without blocking.

2. Belt speed

The proper belt speed depends to a large extent on the nature of the material to be conveyed, the required conveying capacity and the adopted belt tension.

The following factors shall be considered for the selection of belt speed:

Bandwidth: the smaller the tape width is, the less stable it is when running at high speed, and even prone to serious scattering.

Fixed conveyor: generally, the installation quality is relatively high, and higher belt speed is preferred, while the speed of semi fixed and mobile conveyors is relatively low.

When conveying horizontally or nearly horizontally, the speed can be higher. The greater the inclination is, the easier the material is to roll or slide, and the lower speed should be adopted.

Belt conveyor with inclined installation: relatively speaking, the downward belt conveyor should have a lower speed, because the materials are easier to roll and slide on the belt during downward transportation.

The greater the ton kilometer value of the conveying capacity is, the greater the belt strength is required. In order to reduce the belt strength, a higher speed can be used.

The bending of the belt on the roller: the loading impact and the impact of materials cause the wear of the belt, so it is better to slow down the short distance conveyor. However, in order to reduce belt tension, long-distance conveyors often use high-speed operation.

The belt conveyor can complete the conveying capacity required by the system, which is mainly determined by the belt width and belt speed. Belt speed has great influence on belt width, dead weight, cost and working quality of belt conveyor. Under the same conveying capacity, two schemes can be selected: larger bandwidth and lower belt speed, or smaller bandwidth and higher belt speed. The following factors shall be considered when selecting belt speed:

Characteristics and process requirements of conveyed materials

(1) For materials with small abrasiveness and small particles, such as coal, grain, sand, etc., a higher speed should be adopted (generally 2~4m/s).

(2) For materials with high abrasiveness, large blocks and fear of crushing, such as large coal, large ore, coke, etc., low speed (within 1.25~2m/s) is recommended.

(3) For powdery materials or materials with large amount of dust that are easy to raise dust, low speed (≤ 1.0m/s) should be adopted to avoid dust flying.

(4)For goods, easy rolling materials or places with high requirements for environmental health conditions, low speed (≤1.25m/s) is suitable.

Layout and discharge mode of belt conveyor

(1) Long distance and horizontal belt conveyors can choose higher belt speed.

(2) For belt conveyors with large inclination or short conveying distance, the belt speed shall be appropriately reduced.

(3) When the unloading trolley is used for unloading, the belt speed should not be too high, generally not more than 3.15m/s, because the actual inclination of the conveyor belt into the unloading trolley is large.

(4) When the plough unloader is used for discharging, the belt speed should not exceed 2.8m/s due to additional resistance and wear.

(5) The belt speed of downward belt conveyor with large inclination should not exceed 3.15m/s.

The conveyor belt is the main component of the conveyor, which is both a bearing component and a traction component. The cost of the conveyor belt in the conveyor accounts for 30% – 50% of the total equipment cost. Therefore, for the conveyor belt, attention should be paid to the selection of material, belt speed and belt width to ensure the efficient and stable operation of the conveyor.

Web: https://www.sinocoalition.com/

Email: sale@sinocoalition.com

Phone: +86 15640380985

Post time: Jan-11-2023