Low MOQ for Belt Conveyor Pulley/Drum Pulley/Drum Roller, Rubber Roller, Steel Pulley

We support our consumers with ideal high-quality goods and substantial level support. Becoming the specialist manufacturer in this sector, we now have acquired abundant practical encounter in producing and managing for Low MOQ for Belt Conveyor Pulley/Drum Pulley/Drum Roller, Rubber Roller, Steel Pulley, We’ve been glad that we’ve been steadily developing along with the active and long lasting assist of our pleased buyers!

We support our consumers with ideal high-quality goods and substantial level support. Becoming the specialist manufacturer in this sector, we now have acquired abundant practical encounter in producing and managing for China Steel Pulley and Conveyor Rubber Drum, We’ve been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Product Description

According to GB/T 10595-2009 (equivalent to ISO-5048), the service life of the conveyor pulley bearing should be more than 50,000 hours, which means that the user can maintain the bearing and the pulley surface at the same time. The maximum working life can exceed 30 years. The surface and internal structure of multi-metal wear-resistant materials are porous. Grooves on the surface increase drag coefficient and slip resistance. GT conveyor pulleys have good heat dissipation performance, especially under high temperature conditions. Corrosion resistance is another benefit of GT conveyor pulleys. It can also achieve good performance in seaside or other complex conditions. High surface hardness prevents foreign matter (iron or iron filings) from entering the pulley, thereby protecting the pulley.

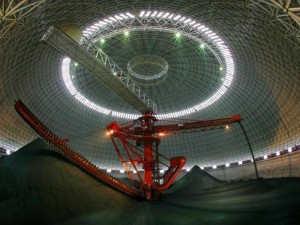

At the same time, Sino Coalition can also produce conveyor pulleys for other forms of conveying equipment, which the drive pulleys have smooth surface and rubber surface, and the rubber surface also has flat rubber surface, herringbone pattern rubber surface (suitable for one-way operation), rhombic pattern rubber surface (suitable for two-way operation), etc.Driving pulley adopts cast welding structure, expansion sleeve connection and cast rubber rhomb type rubber surface, double shaft type. The structure is shown in the following figure:

Pulley diameter and width (mm): Φ 1250,1600

Bearing lubrication mode and grease: centralized lubrication lithium base grease

Bearing sealing mode: labyrinth seal

Wrap angle of driving pulley: 200 °

Service life: 30000h

Design life: 50000h

The reversing pulley adopts flat rubber surface. The reversing pulley with the same diameter adopt the same structural type, and the combined tension is considered according to the maximum calculated value. The specific structural form shown in the following figure:

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top