High Quality Mining Apron Feeder - High efficiency Mobile Material Surface Feeder – Sino Coalition

High Quality Mining Apron Feeder - High efficiency Mobile Material Surface Feeder – Sino Coalition Detail:

Introduction

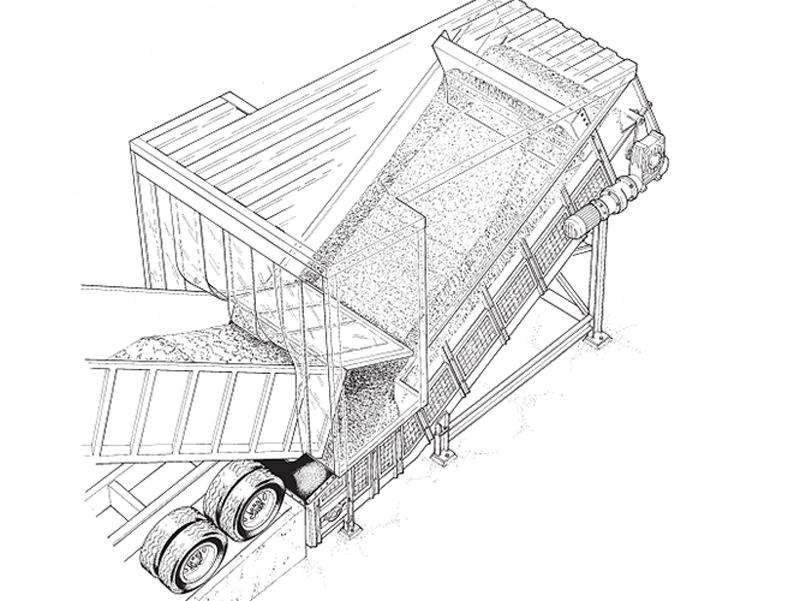

Surface Feeder is developed to meet the user’s need for mobile material receiving and anti-leakage. The equipment can reach the capacity up to 1500t/h, max belt width 2400mm, max belt length 50m. According to various materials, max upwards inclination degree is 23°.

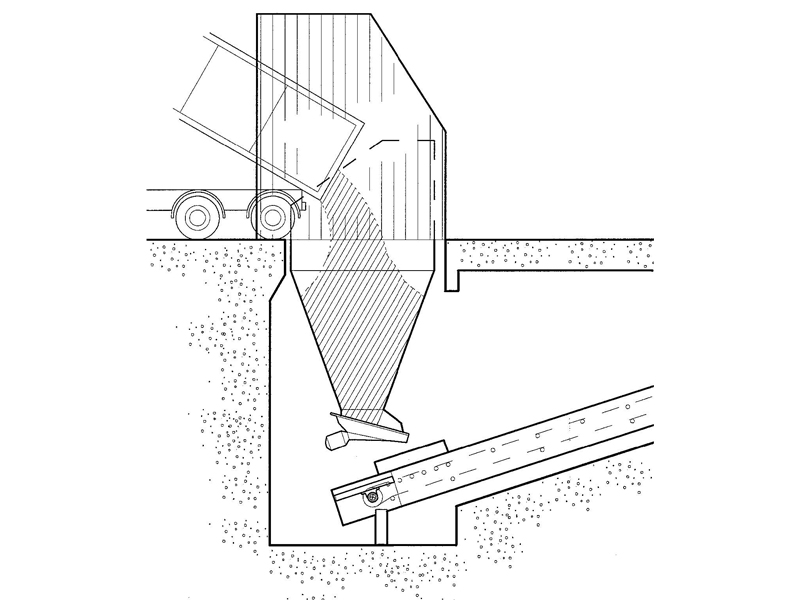

In the traditional unloading mode, the dumper is unloaded into the feeding device through the underground funnel, then transferred to the underground belt and then transported to the processing area. Compared with the traditional unloading method, it has the characteristics of no pit, no underground funnel, no high civil construction cost, flexible setting location, integrated whole machine and so on.

From a functional point of view, the equipment can be divided into parallel feeding section and upward feeding section (according to the actual situation upward feeding section can also be arranged in parallel).

Structure

The equipment is composed of driving device, spindle device, tensioning shaft device, chain plate device (including chain plate and tape), chain, frame,baffle plate(sealed cabin), leakage proof device, etc.

Independent feeders are usually equipped with direct motor drive to cooperate with parallel or orthogonal shaft reducers installed on the extended shaft of the head. In special applications, tandem reducers or hydraulic drives can be used.

Operating

Material tilting from the dump truck to plate feeder specific operation is divided into three steps.

1. Firstly, the material is inclined from the dump truck to the plate feeder running forward to the belt conveyor With the operation of the belt conveyor, the materials completely tilt down from the tipper.

2. After the materials are completely tilted, the dump truck leaves, the materials are transferred to the downstream conveying system, and the inlet is empty.

3. After the first dump truck has left, the other one is in place. During this period, the plate feeder has transported the materials to the downstream, and the inlet can accept the new materials.

4. Such operation, cycle and repeat.

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for High Quality Mining Apron Feeder - High efficiency Mobile Material Surface Feeder – Sino Coalition , The product will supply to all over the world, such as: Czech, Vietnam, Croatia, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top