Fluid Couplings

Introduction

Shenyang Sino Coalition Machinery Equipment Manufacturing Co., Ltd. produces YOP and YOX series of fluid couplings, which are designed on the basis of selecting the most ideal cavities. This series of products has a reasonable design, compact structure, reliable operation, significant energy-saving effect, no leakage, and good performance, reaching the international level of similar products.

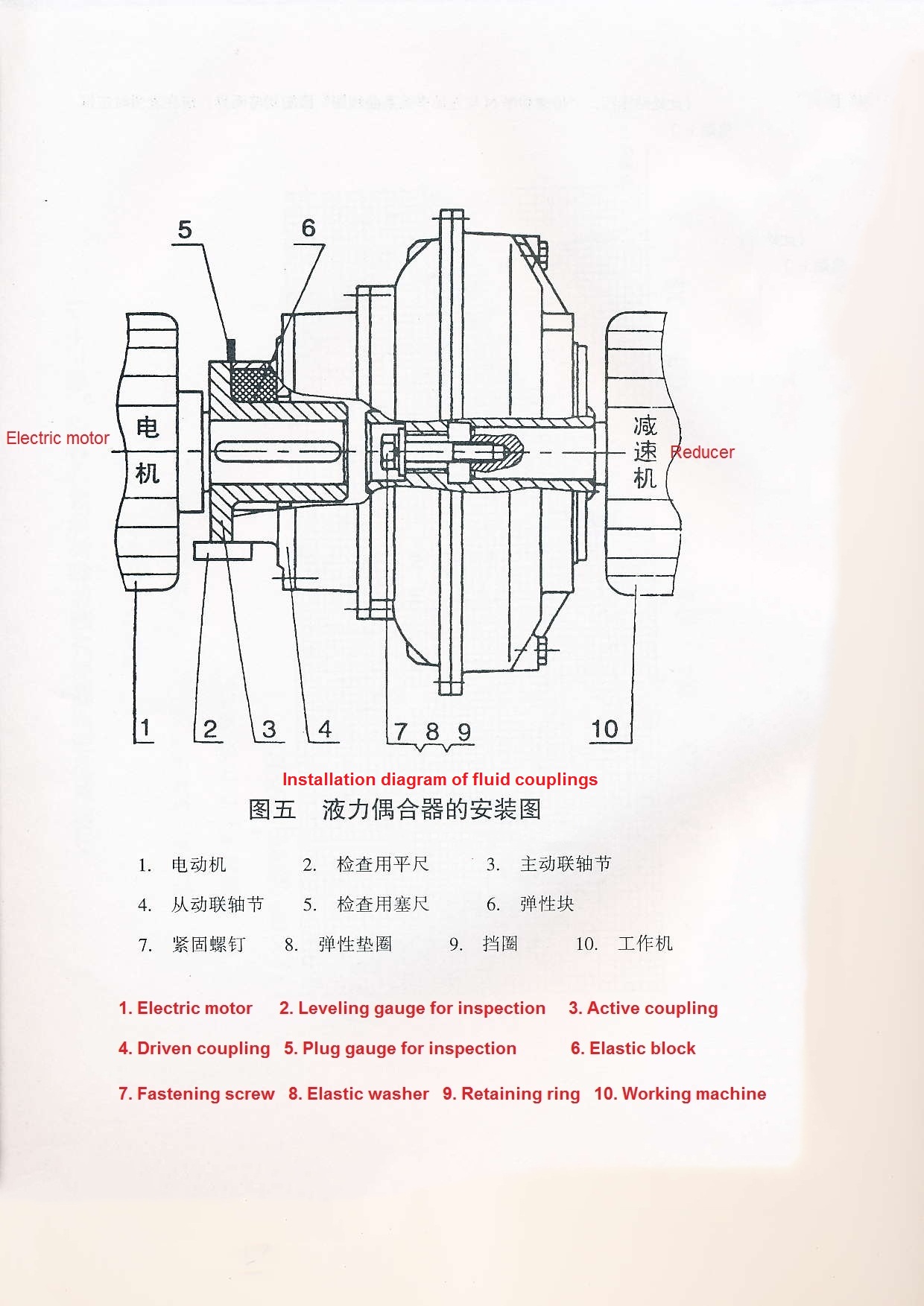

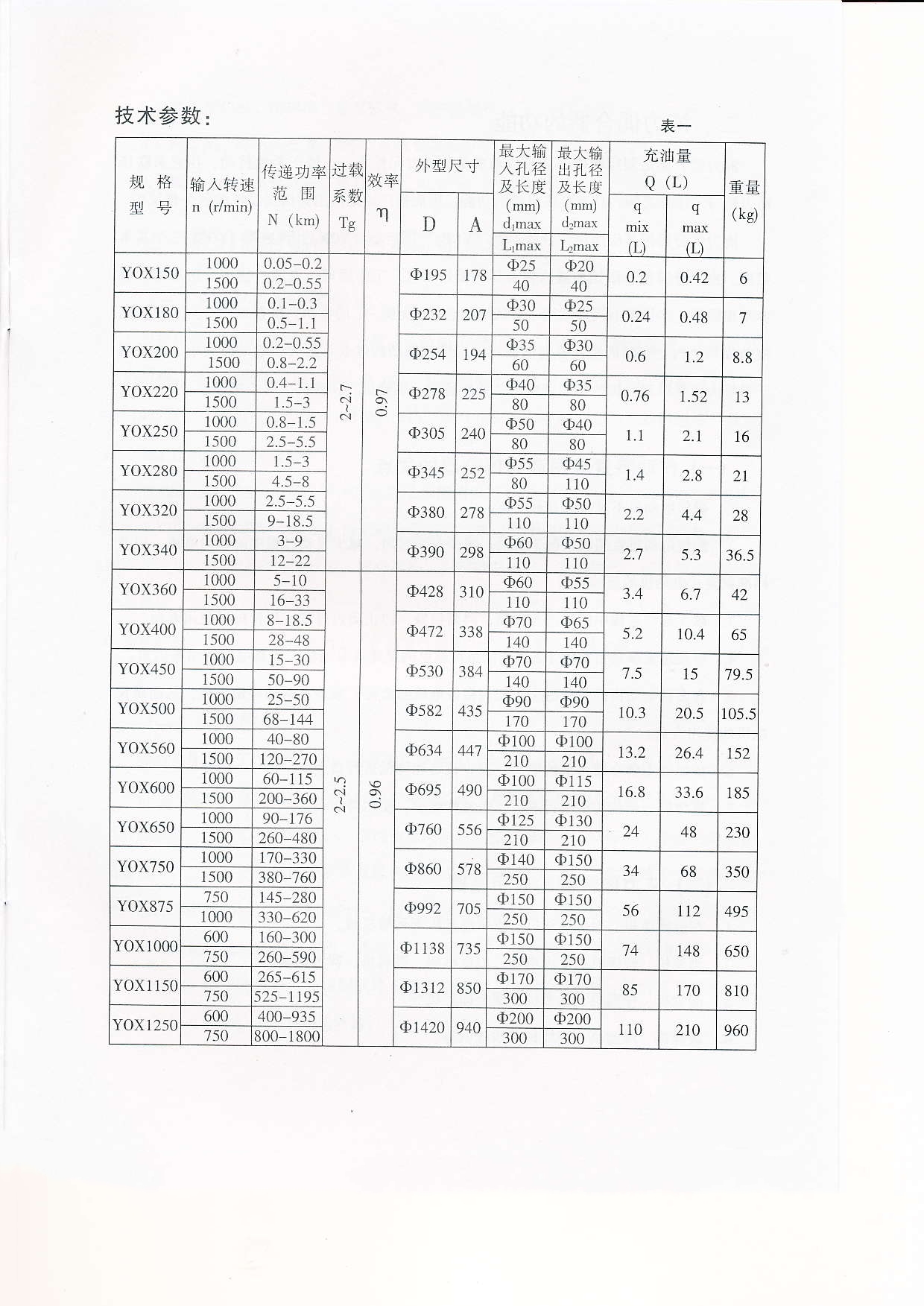

Fluid couplings are divided into three basic types based on their application characteristics: ordinary type (YOP), limited torque type (YOX), and variable speed type (YOT). As the operating conditions, working principles, installation, usage methods, and maintenance of ordinary and limited torque fluid couplings are the same, this manual also applies to the use and maintenance instructions of ordinary couplings (see Figure 1). However, due to some differences in the filling curve and structure, the overload coefficient for starting and braking of ordinary couplings is large, the starting time is small, and they are mostly suitable for transmission systems with high inertia and fast starting requirements, such as ball mills, crushers, drum machines, centrifuges, etc.

Advantages of hydraulic couplings

1. Ensure that the electric motor does not stall or get stuck.

2.Enables the motor to start under overload, reduces the starting time, reduces the average current during starting, and improves the starting capacity of standard squirrel-cage motors.

3.Reduce the impact and vibration during the starting process, isolate torsional vibration, prevent power overload, and extend the service life of the machinery.

4.A simple structure squirrel cage motor can be selected at 1.2 times the normal rated load to improve the power factor of the power grid

5.In the transmission chain of multiple motors, it can balance the load of each motor, reduce the impact current of the power grid, and thus prolong

The service life of the motor.

6.The application of hydraulic couplings can save energy, reduce equipment, and lower operating costs

7.The structure of hydraulic coupling is simple and reliable, no special maintenance is needed, and the service life is long

Application scope of hydraulic coupling

1.Scraper conveyor, plate conveyor, belt conveyor and other transportation machinery.

2.Coal planer, coal milling machine, mining machinery, metallurgical machinery, mixing machine, feed machinery

3.Cranes, excavators, loaders, screw unloaders, etc.

4.Crushers, ball mills, winding machines, wire drawing machines, etc

5. Air preheaters, mixers, construction machinery, ceramic machinery, etc.

6.Traveling and slewing of automobile crane and tower crane Reeling part, etc.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top