Factory Supply China Manufacturer Supply Sustained Bucket Wheel Stacker Reclaimer

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Factory Supply China Manufacturer Supply Sustained Bucket Wheel Stacker Reclaimer, We warmly welcome merchants from home and overseas to connect with us and create organization romance with us, and we’ll do our greatest to serve you.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for China Ship Unloader and Designed by Client′s Requirements, With the advanced workshop, specialist design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our solutions are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

Introduction

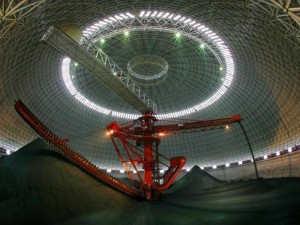

Top stacking and lateral reclaiming stacker reclaimer is a type of indoor circular stockyard storage equipment. It is mainly composed of a cantilever slewing stacker, a central pillar, a side scraper reclaimer (portal scraper reclaimer), electric control system and so on. The central pillar is set in the center of the circular stockyard. On its upper part, a cantilever stacker is mounted, which can 360°rotate around the pillar and completes stacking in cone-shell method.The side reclaimer (portal scraper reclaimer) also rotates around the central pillar. By the reciprocation of the scraper on the reclaimer boom, the material is scraped off layer by layer to the discharge funnel under the central pillar, then unloaded to the overland belt conveyor for being transported out of the yard.

The equipment can achieve continuous stacking and reclaiming operation in full automatic process. Sino Coalition is one of the companies that produce full specifications of top stacking and lateral reclaiming stacker reclaimer. At present, the equipment diameter and corresponding silo storage capacity that can be manufactured are 60m (15000-28000 m3), 70m (2300-42000 m3), 80m (35000-65000 m3), 90m (49000-94000 m3), 100m (56000-125000 M3), 110m (80000-17000 m3), 120m (12-23 m3) and 136m (140000-35000 m3). The top stacking and lateral reclaiming stacker reclaimer with a diameter of 136m has reached the world advanced level. The range of stacking capacity is 0-5000 T / h, and the range of reclaiming capacity is 0-4000 T / h.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top