Factory made hot-sale Pipe Rubber Conveyor Belt Material Handling Conveying Equipment Automatic Belt Conveyor for Truck Loading Unloading Suitable for Plastic Recycling Machine

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for Factory made hot-sale Pipe Rubber Conveyor Belt Material Handling Conveying Equipment Automatic Belt Conveyor for Truck Loading Unloading Suitable for Plastic Recycling Machine, We welcome you to definitely inquire us by simply call or mail and hope to build a successful and cooperative romance.

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for China Pipe Rubber Conveyor Belt and Wear Resistant Rubber Belt, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers’ expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Structure

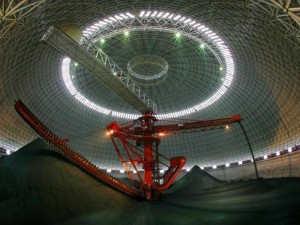

The pipe belt conveyor is one kind of materials conveying device in which the rollers arranged in a hexagonal shape force the belt to be wrapped into circular tube. The head, tail, feeding point, emptying point, tensioning device and the like of the device are basically same in structure with the conventional belt conveyor. After the conveyor belt is fed in the tail transition transition section, it is gradually rolled into a circular tube, with material transported in sealed condition, and then it is gradually unfolded in the head transition section till unloading.

Features

·During the conveying process of the pipe belt conveyor, the materials are in a closed environment and will not pollute the environment such as material spilling, flying and leakage. Realizing harmless transportation and environmental protection.

·As the conveyor belt is formed into circular tube, it can realize large curvature turns in vertical and horizontal planes, so as to easily bypass various obstacles and cross roads, railways and rivers without intermediate transfer.

·No deviation, the conveyor belt will not deviate.Deviation monitoring devices and systems are not required throughout the process, reducing the maintenance cost.

·Two-way conveying of materials to improve the efficiency of the conveying system.

·Meet multi-field applications, suitable for various material conveying.On the conveying line, under the special process requirements of the circular pipe belt conveyor, the tubular belt conveyor can realize one-way material transportation and two-way material transportation, in which the one-way material transportation can be divided into one-way pipe forming and two-way pipe forming.

·The belt used in the pipe conveyor is close to the ordinary one, so it is easy to accept by the user.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top